The vinification work depends on the quality of the grapes at the harvest.

Conditions change every year. Decisions concerning the vinification have to be taken by analysing, tasting, listening, and smelling, all of this according to the result desired.

Experience gained over more than 30 years, knowledge, and a sufficiant dose of observation help us to guide nature towards a perfect wine in each tank.

receiving the grapes

The design of our cellar enables us to do a gravity vatting : the grape follows the shortest path, thus preserving as much integrity and quality as possible.

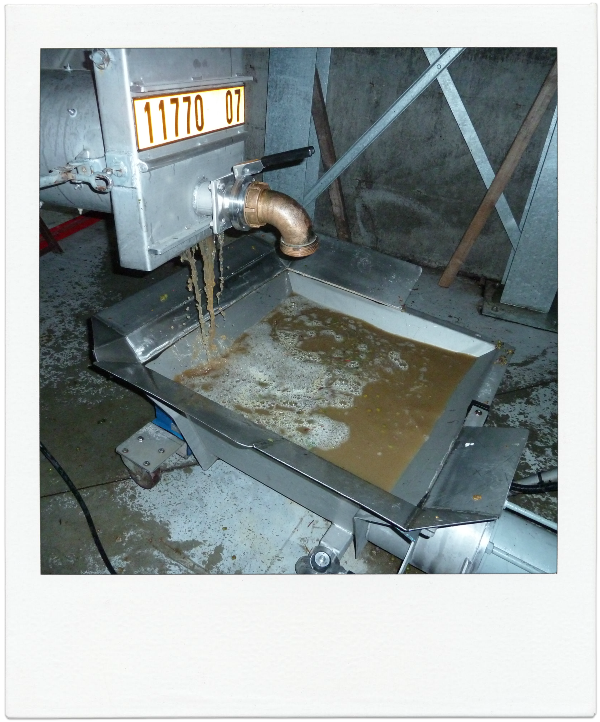

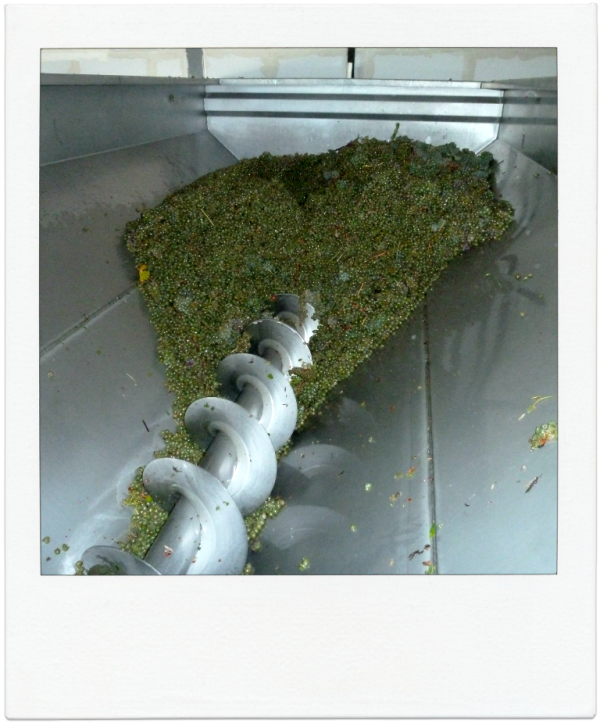

THE TRAILER

The trailer is made of stainless steel and has an auger, a sluice gate, and a trapdoor.

The sluice gate lets the juice flow before opening the trapdoor and starting up the auger : the grapes slowly come out.

Our new mechanical harvester has an integrated de-stemmer that gets rid of the stems. As a result, only the grape berries reach our cellar.

The stems stay in the vines, and will naturally return to the ground.

THE GRAPE BOXES

The manually harvested grapes are qualitatively sorted directly on the vine base : we only harvest ripe and healthy grapes. Dropped off in grape boxes, they do not get crushed and arrive at the cellar in full bunches, almost intact.

The boxes must be emptied one by one into our tanks : another difficult job ! This particular attention is intended for our natural wines and our Syrah, for which we prefer a carbonic maceration.

the maceration

TRADITIONAL

For the vinification of the red wines, the grapes stay in the tanks 5 days to 5 weeks before being pressed.

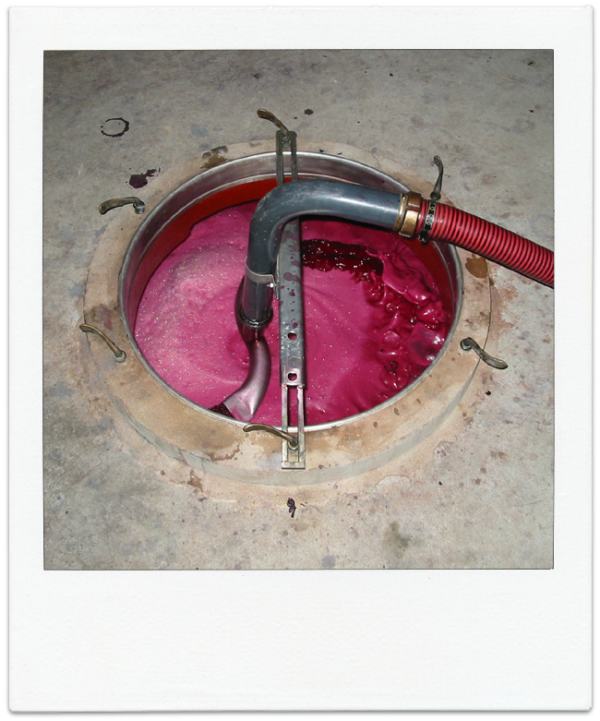

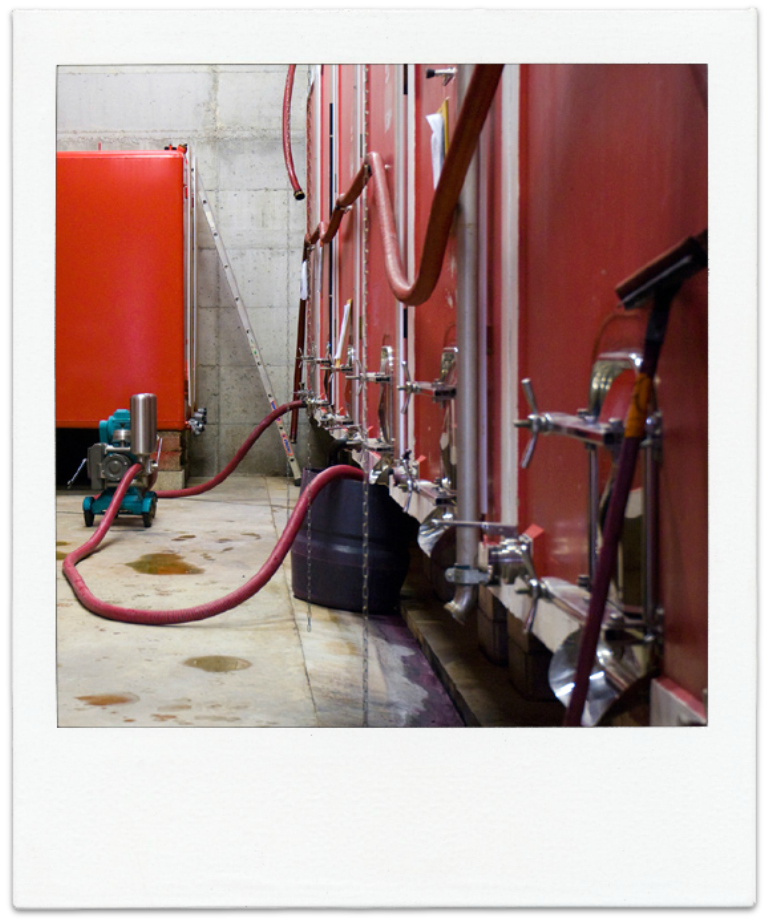

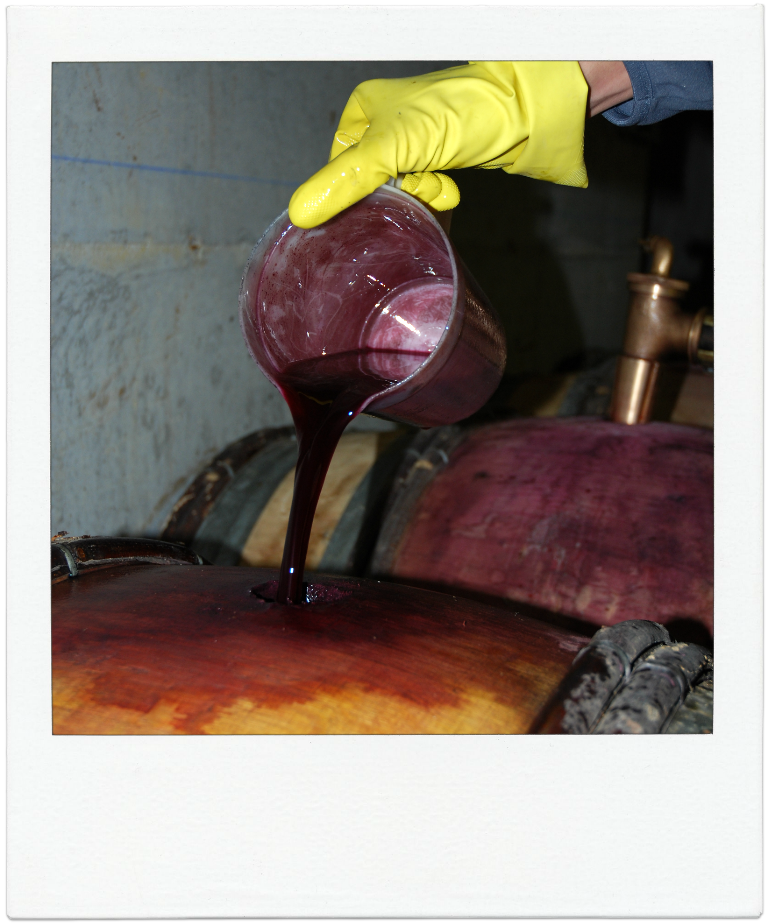

During this period of alcoholic fermentation, we proceed to pumping-over : the grape juice located in the bottom of the tank is pumped up and poured back into the top of the tank, going through the marc cap.

The purpose of this process is to supply oxygen to the yeasts, homogenize the environment, and favourise the exchanges between solid and liquid matter.

CARBONIC MACERATION

For our natural red wines, the grapes are harvested in full bunches and put into vats as they are, with minimum grinding. They will stay in the tanks for about 12 to 15 days without any intervention. This favours the intracellular fermentation, that consists in transforming the sugar into alcohol by enzymes that are naturally present in the grapes. The alcoholic fermentation due to the yeasts will finish the job. This vinification technique brings intense aromas and suppleness to the wines.

In the presence of oxygen (aerobic) , the grapes "breathe".

When all of the oxygen is replaced by carbon dioxide, the bays can no longer breathe. They then go through an anaerobic internal fermentation, without any intervention from the yeasts.

As we use the term of fermentation for transformations due to micro-organisms (yeasts and bacteria), we would rather use the term anaerobic metabolism for transformations that happen inside the fruit, in an atmosphere saturated with carbon dioxide.

The consequences of carbonic maceration are :

- the production of a small degree of alcohol through the transformation of the sugar (limits the alcoholic content)

- rich and intense aromas

- creation of growth factors for the yeasts and bacteria.

Lactic and malo-lactic fermentations will unfold faster than in the case of a traditional maceration.

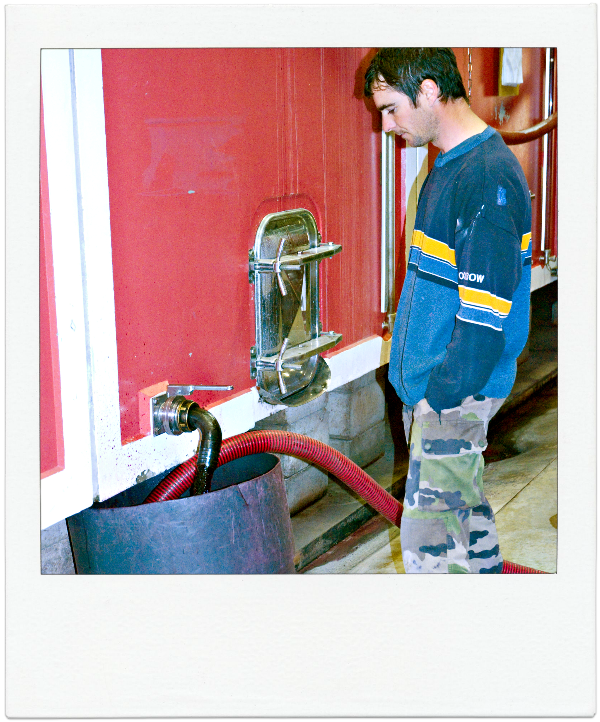

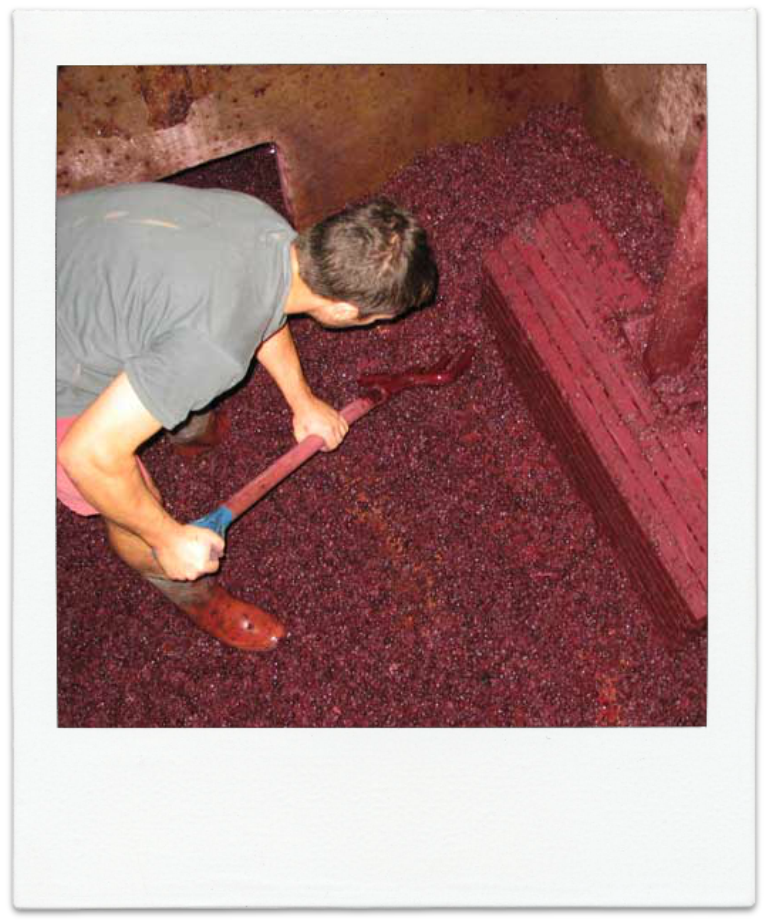

devatting

Once the juice is extracted at the end of the maceration, we take the grape (marc) out with a fork. It is then transferred to the wine-press thanks to a marc pump.

Following on this, we clean out the tanks with water.

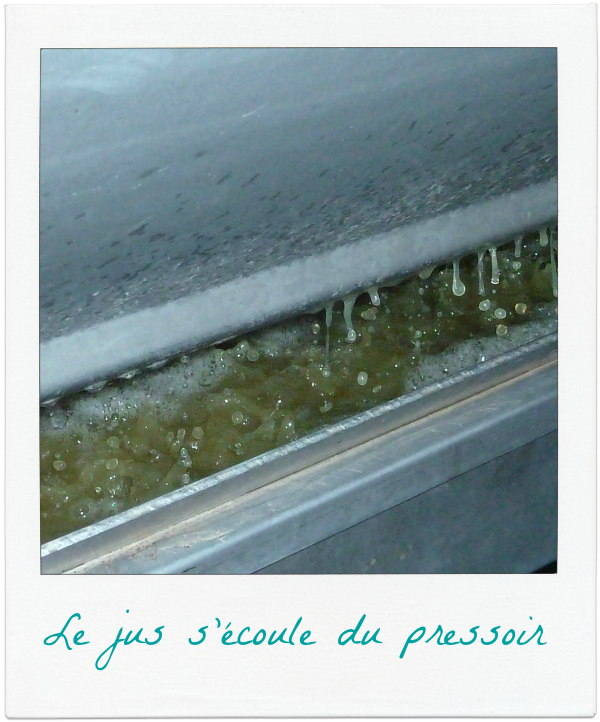

pressing

For the white wine vinification, the grapes are generally pressed directly after the harvest and the fermentation takes place on clear juice.

For the red wines that we want fruity and light in tannins, we proceed to pressing as soon as the fermentation is over. As for the red wines made to be kept, we choose to wait 5 weeks before pressing, in order to gently extract more tannins.

By state obligation, the marc is transported to a distillery in Vallon Pont d'Arc.

There, the different componants of the marc are brought out :

- alcohol and acids are extracted

- seeds are used to produce oil (grape seed oil)

- anthocyanins (or polyphenols) will be used for cosmetics...

The left-over matter will be composted, to then be reused as a soil improver in the vines.

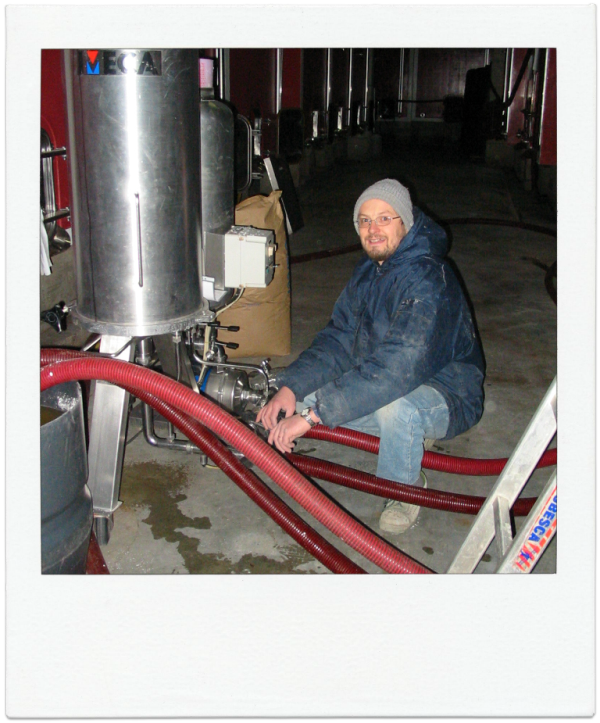

maturing

We keep our wines at a temperature of 20°C to favorise the malo-lactic fermentation. Solar panels heat up the vats that contain our red wines, our chardonnay, and our viognier. These solar panels are equiped with coils that run in the walls of the vats. This enables a slight deacidification of the wine, and brings roundness. The wines are totally stable, and present no risk of refermentation once they are bottled. As for our other wines, we prefer to keep the freshness and not proceed to this fermentation.

The phenomenon is the transformation of the malic acid into lactic acid (a strong acid into a less strong acid) thanks to the lactic bacteria found in the grape.

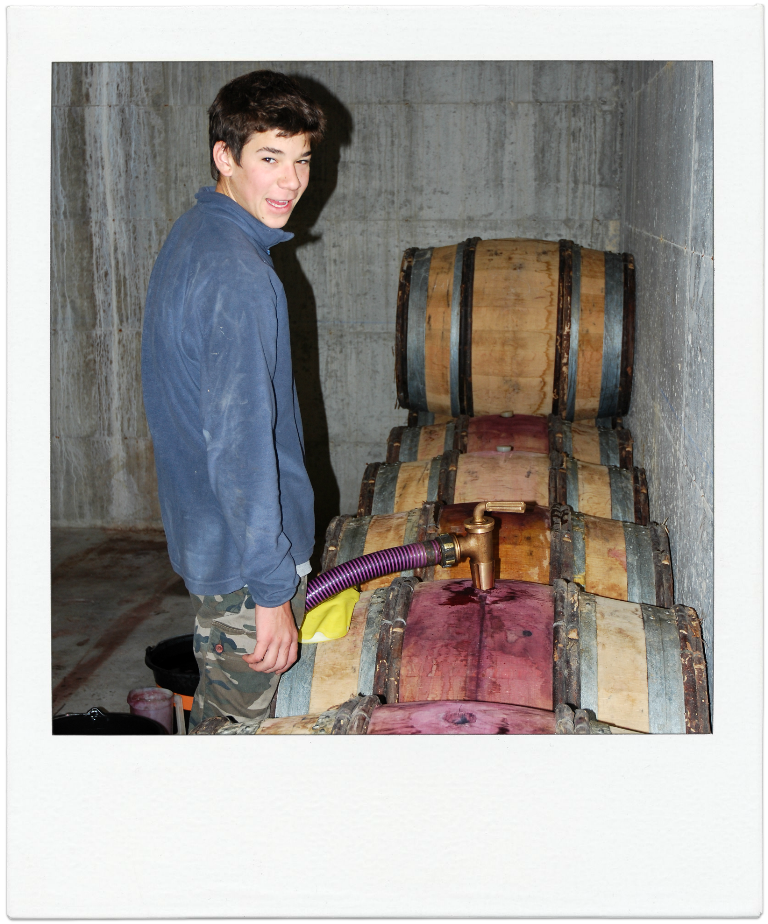

IN OAK BARRELS

The tannin quality of our best Syrah and Chardonnay plots allow a passage in oak barrels.

The cask lets oxygen slowly seep into the wood, thus polishing the wines that are better able to age.

The barrels we use are an average of 3 years old. Their aromatic power is already diminished, and the wood will not mask the natural aromas of our grape varieties.

Raising in oak barrels does not last longer than 9 months, and remains a gentle and delicate way to air our most noble wines without rushing them.

IN TANKS

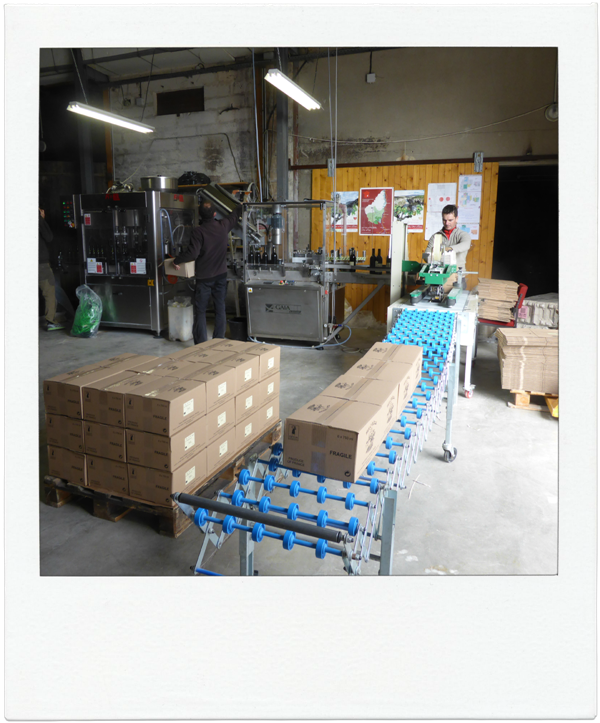

bottling

We have our own bottling line and labeler. This tool allows for a meticulous job to be done, especially for putting on the front and back labels.

As we do not depend on an external party for this job, we can bottle our wines when the time is best for them.

The wines with no sulfites are more fragile, and will preferably be bottled during fruit days according to the lunar calendar.

Wow, the wine must be super good, then!

But where can I find this wine?